|

|

| |

|

| |

| |

|

| |

|

|

Sonatest – AlphaGage+ Series

The AlphaGage+ series is a range of hand-held ultrasonic thickness gauges available for Corrosion, Precision or combined for both. It is definitely a key asset for inspectors, maintenance operators or QA technicians looking to measure essentially any engineering material thickness as it combines years of ultrasonic design and knowhow.

AphaGage+ Precision

An instrument uses single element transducers in Pulse-Echo configuration in order to measure to higher accuracy than corrosion gages and meet very strict quality control requirements as in the Aerospace and Automotive industries. Typical applications include: Steel, Aluminium, Glass, Plastic & Rubber.

|

|

|

| |

|

|

| |

|

AphaGage+ Corrosion

It is a instrument uses dual element transducers in a Pitch & Catch configuration to reduce surface problems and to measure accurately the remaining wall thickness of these metal structures subject to corrosion. Typical applications include: metal pipe works, pressure vessels, structural parts & storage tanks.

|

|

|

| |

|

|

| |

|

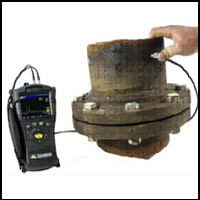

Sonatest T-Gage IV Series

The T-Gage IV Series has been designed and built for use in the harshest of industry conditions. The features offered allow the user to select a quality tool that will meet their specific application needs.

Other models within this range include the T-Gage IV+, T-Gage IV DL, T-Gage IV MM and the T-Gage IV MM DL.

Typical applications include: Corrosion & Pitting, Tube & Pipe, Tanks & Boilers, Glass, Plastics- polypropylene etc (T-Gage IV+/DL only) and a variety of other applications.

|

|

|

| |

|

|

| |

|

Betagage

- Measures 0.63-254mm in I-E mode (1st echo) .

- 2.54-102mm in E-E mode (through paint).

- Hi/Lo tolerances with audible/visual alarms.

- Stability indicator, bar graph and visual cursors for reading confirmation.

- Material velocities can be recalled from in-built library

- Stores 64 user definable set-ups for calibrations.

- Alphanumeric storage for 12000 A-Scans with thickness readings

- Includes RS232 cable and Windows interface software

|

|

|

| |

|

|

| |

|

Sonatest - CT Gage Series

The CT Gage Range has been designed as a multi-purpose ultrasonic material and coating thickness instrument with a wide range of features. It can able to simultaneously and independently measure the material and the coating thickness, or switch to the time based B-Scan view to see a cross section view of the material you are inspecting. A custom calibration configuration for both the material and coating types offers extreme linearity.

CT-Gage DL includes all of the above features but it also equipped with a Data Logger. The Data Logger consists of two file formats; Sequential logging with auto identifiers and an alpha-numeric grid. The DL can store 16,000+ readings, with B-Scan captures, recording all the gauge's settings and features, or turn the graphics mode off and store over 210,000 readings!

CT-Gage DL+ enables A-Scan measurements to be taken and stored. This model also includes Time Corrected Gain features.

CT-Gage DL+ C includes all of the above features but is also equipped with a High speed colour screen option with a screen option with a screen refresh rate of 60 Hz.

|

|

|

|

| |

|

|

|